Breaking the Bottleneck | Issue 26

[10/1/2023] America's Advanced Manufacturing Problem, IFR Robot Report 2023,& 3D Printing w/ Drones

Breaking the Bottleneck is a weekly manufacturing technology newsletter with perspectives, interviews, news, funding announcements, and a startup database. For an older version of a discrete and continuous manufacturing market map click the link here!

Content I Enjoyed This Week 🏭🗞️🔬

News:

America’s Advanced Manufacturing Problem & How to Fix It [American Affairs]

Amazing long-form work on whether or not the United States still can make things domestically, where America lacks capabilities for advanced manufacturing, and where the most recent round of industrial policies have fallen short.

Inside Apple’s Spectacular Failure to Build a Key iPhone Part [WSJ]

Apple failed in its attempt to develop its modem chip for iPhones, a project initiated in 2018 to reduce dependence on Qualcomm, whom they accused of overcharging in a 2017 lawsuit. Apple aimed to replicate the success it had with designing microprocessor chips but faced obstacles, including technical challenges and poor communication among engineering teams. The proprietary modem chip, codenamed Sinope, was found to be too slow and prone to overheating during tests late last year. Its circuit board was too large, making it unusable for iPhones. The companies settled the lawsuit in 2019, and Apple recently extended its agreement to buy Qualcomm's modem chips through 2026. Apple is not expected to produce a comparable chip until late 2025, with potential further delays. The complexity of designing modem chips, which must comply with strict connectivity standards for wireless carriers globally, led to unrealistic timelines, and a lack of experience in wireless chip design contributed to the project's setbacks.

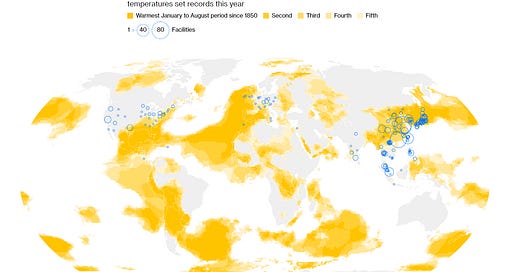

Apple’s Supply Chain Crash Course w/ Climate Change [Bloomberg Opinion]

Apple's vast supply chain is potentially vulnerable to the impacts of climate change, despite the company's commitment to environmental sustainability. While Apple has made significant strides in reducing its carbon footprint and aims for net-zero climate impact on all devices by 2030, the geographic locations of its suppliers and manufacturing facilities expose it to climate-related risks. Apple is not the only electronics company vulnerable to climate risks. The analysis indicates Samsung, Sony, and Dell are also in many of the regions most vulnerable to climate change, such as those prone to floods, extreme weather events, and heatwaves. The Asian manufacturing belt, from India to Japan, where these companies have a significant presence will need to be re-evaluated and future-proofed to ensure that these companies can hedge against flood risk, power generation dependence on fossil fuels, and potential carbon leakage.

ABB Launches OptiFact Software [ABB]

ABB Robotics has introduced the OptiFact software platform, designed to streamline data collection, visualization, and analysis in automated production facilities. The platform facilitates the collection and analysis of data from various factory devices, including ABB robots, to assess key performance indicators such as cycle time and OEE. OptiFact aims to accelerate diagnostics and decision-making, leading to increased production line uptime with reduced engineering effort. The platform is part of ABB's new digital solutions, catering to the growing demand for automation solutions, sustainable manufacturing, and the impact of the pandemic. It has been successfully deployed in various production environments, including automotive production, demonstrating significant time savings and operational efficiencies. OptiFact integrates with ABB's RobotStudio Cloud, allowing operators to identify and address production errors and make adjustments to robotic programs for improved solutions.

How Deep Tech Drives Sustainability and Profitability in Manufacturing [HBR]

Manufacturers are facing a shift in priorities from traditional goals of speed, quality, and cost efficiency to a focus on sustainability as a strategic imperative. Key factors enabling this shift include the rising urgency for sustainability driven by net-zero commitments, increased financial and regulatory support for green technologies, and the transition of transformative technologies from labs to the real world. Deep tech can enhance the profitability-sustainability profile of products by reimagining the essence of products, using new materials, changing product performance profiles, and contributing to the supply and price stability of raw materials. Examples include companies like Geno and Modern Meadow developing sustainable alternatives in the beauty and apparel industries, Niron Magnetics' magnets made from abundant nitrogen & iron, Boston Metal's electrolytic process for steelmaking, Syzygy Plasmonics' scalable photoreactor, and new production enablers like small, cellular factories. Finally, it argues that collaboration, rather than competition, is crucial such as LanzaTech's collaboration with BASF to convert industrial process gases into bioethanol.

Research:

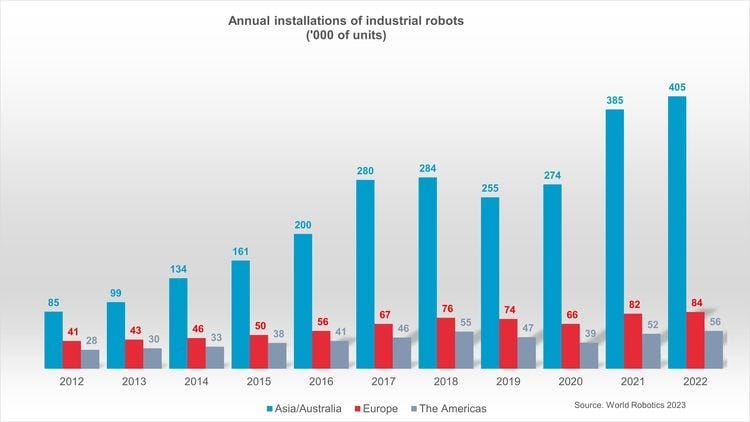

World Robotics 2023 Report [IFR]

In the Americas, installations were up 8% to 56,053 units in 2022, surpassing the 2018 peak level (55,212 units). The United States, the largest regional market, accounted for 71% of the installations in the Americas in 2022. Robot installations were up by 10% to 39,576 units. This was just shy of the peak level of 40,373 units achieved in 2018. The main growth driver was the automotive industry which displayed surging installations by +47% (14,472 units). The share of the automotive industry has now grown back to 37%, followed by the metal and machinery industry (3,900 units) and the electrical/electronics industry (3,732 units).

X-Force Threat Intelligence Index [IBM]

Manufacturing continues to be the highest-targetted OT sector with spear phishing (38%) including the use of attachments (22%), links (14%), and services (2%) serving as the main access vector. Other common attack vectors for manufacturing included public-facing applications (24%), detection of backdoors (20%), and ransomware (19%). These all stem from the lack of proper segmentation between OT and IT networks. These environments include targeting jump servers, dual-homed operator workstations, and reporting servers, such as data historians that expose web and SQL services from OT to corporate IT networks. Properly segmenting these portions of your networks and closely monitoring communication across them can keep assets safe.

Podcasts:

Hardware ReInvented [Manufacturing Hub]

Digital Transformation Advice w/ Vatsal Shah [Mfg Happy Hour]

3D Printing w/ Drones [MIT]

Chart of the Week:

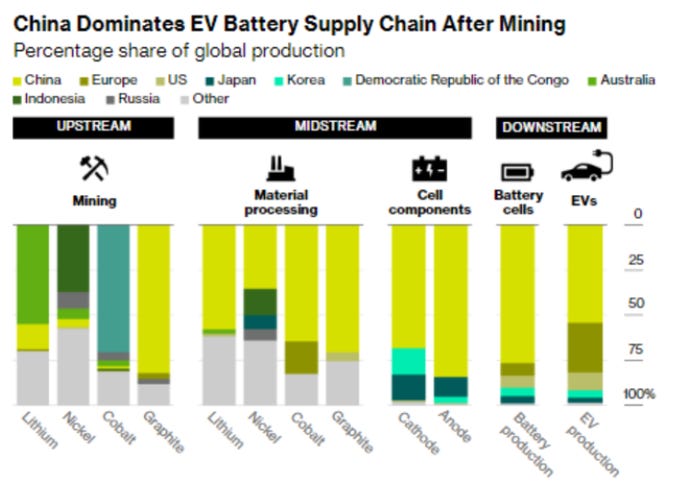

China has about 70% of the world’s production capacity of cathodes and >80% of anodes, and well over half of electrolyte and separator output

Track the Clean Manufacturing Factories Being Built Across the US

Manufacturing Deals

Kneron - A company edicated to the design and development of integrated software and hardware edge AI solutions

$49 million [Series B Extension] - From Foxconn, Alltek, Horizon Ventures, Liteon Technology, Adata and Palpilo

Unit X - A company helping automate visual inspection lines in factories to improve cycle time and reduce defects

$5 million [Venture] - Led by SE Ventures

Weekly Planned Downtime

Inside Luxury’s Secret India Supply Chain