Breaking the Bottleneck | Issue 70

[1/27/2024] MatterGen, What's Next For Robots, & Physical Intelligence's FAST!

Breaking the Bottleneck is a weekly manufacturing technology newsletter with perspectives, interviews, news, funding announcements, manufacturing market maps, and a startup database!

💥 If you are building, operating, or investing in manufacturing, hardware, or robots, please reach out. My email is aditya@schematicventures.com – I’d love to chat!

🏭 If you were forwarded this and found it interesting, please sign up!

Content I Enjoyed Last Week 🏭🗞️🔬 📚

News:

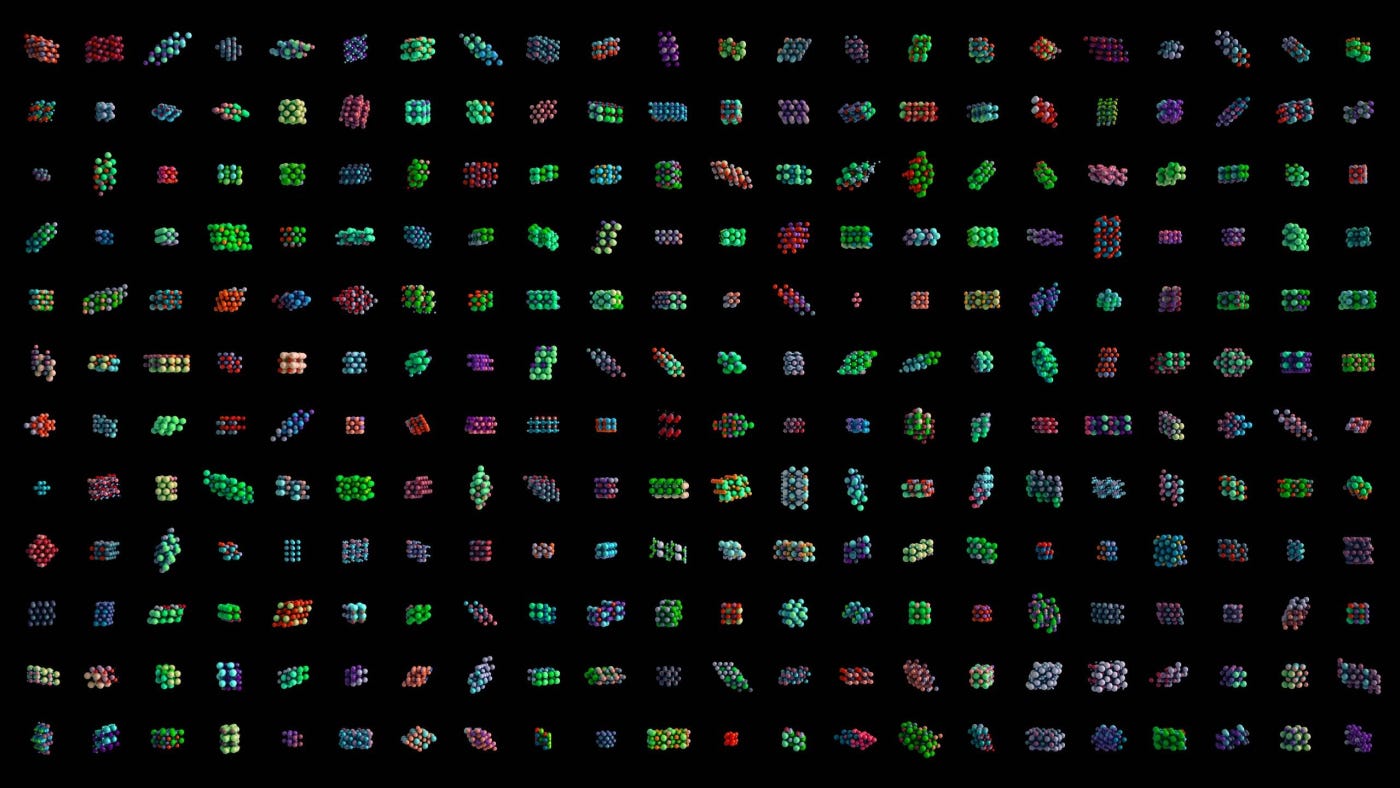

MatterGen: A New Paradigm of Materials Design [Microsoft]

MatterGen, a generative AI tool introduced in a recent Nature publication, is revolutionizing materials discovery by generating novel materials directly from design requirements, bypassing the limitations of traditional screening methods. Historically, finding new materials has been a slow, expensive trial-and-error process, even with a computational screening of large databases. MatterGen, however, uses a diffusion model explicitly designed for 3D material geometry, enabling it to generate stable, unique, and diverse material structures based on desired chemical, mechanical, electronic, or magnetic properties. Trained on over 600,000 stable materials from prominent databases, MatterGen outperforms traditional screening methods by accessing a vast space of unknown materials. For example, it successfully generated more than 100 novel materials with a bulk modulus exceeding 400 GPa, a task where traditional screening plateaued after identifying around 40 candidates. This capability makes MatterGen particularly effective for exploring high-performance materials for applications like batteries, solar cells, and carbon recycling. MatterGen also addresses challenges like compositional disorder, where atomic randomness in materials complicates uniqueness assessments. It introduces a new structure-matching algorithm to evaluate such materials, enhancing the model’s computational evaluation metrics. The public release of MatterGen’s source code and data aims to democratize its use, inviting further innovation in domains like fuel cells, magnets, and battery technologies. MatterGen exemplifies how generative AI might redefine materials design, leading to breakthroughs across various industries.

China Has a $1 Trillion Head Start in Any Tariff Fight [WSJ]

China’s dominance in global manufacturing has grown significantly since Donald Trump first introduced tariffs on Chinese imports in 2018, with the country now accounting for 27% of global industrial production, up from 24% in 2018. In 2024, China posted a record trade surplus of nearly $1 trillion, triple its 2018 level, highlighting its robust export capacity despite efforts by the U.S. and its allies to reduce dependency on Chinese manufacturing. China has countered Western tariffs and industrial policies by subsidizing factories, finding new global customers, and relocating production to other countries. While tariffs under Trump and Biden spurred U.S. investments in manufacturing, particularly in semiconductors, China’s goods surplus with the U.S. still grew 23% to $360 billion in 2024. Much of the U.S.’s electronic, pharmaceutical, and machinery imports are still tied to Chinese supply chains. Similarly, China’s surplus with the EU has more than doubled since 2018, reaching $250 billion. Efforts to curb China’s dominance face limitations. Some experts argue that U.S. consumption habits, including high government borrowing and low savings, also contribute to trade imbalances. Addressing China’s manufacturing dominance may require significant economic reforms in China and the U.S., with tariffs alone unlikely to resolve the issue. Ultimately, China’s manufacturing surplus reflects its deep entrenchment in global trade, and its dominance is expected to persist, reshaping economic strategies worldwide.

Searching for ROI from AI in 2025 [Engineering.com]

According to Qaiser Habib, head of Canada engineering at Snowflake, adopting artificial intelligence (AI) in manufacturing is transitioning from speculative experimentation to delivering measurable business impact. AI is no longer just hype; manufacturers of all sizes, from enterprises to small businesses, find practical applications that yield significant returns on investment (ROI). Habib predicts that 2025 will be marked by a strong emphasis on operationalizing AI solutions focusing on financial impact, moving away from “AI for AI’s sake.” In manufacturing, enterprise AI applications, such as computer vision systems for quality control, are transforming production by reducing inspection times, detecting subtle defects, and enabling continuous, fatigue-free inspections. Projects that demonstrate clear ROI within defined timeframes will dominate, while speculative initiatives will take a backseat. Habib also predicts that AI-as-a-Service (AIaaS) will revolutionize AI adoption in 2025 by making AI tools and applications accessible as cloud-based services. This approach reduces upfront costs, eliminates the need for extensive in-house development, and allows companies to integrate AI capabilities seamlessly into existing systems. For example, manufacturers can use AIaaS for demand forecasting, digital twin simulations, or automated quality inspections. AIaaS also creates opportunities for engineers to develop and monetize their AI applications, akin to the transformation seen with mobile app stores. Finally, he believes that for small and medium-sized manufacturers, the AI sweet spot lies in implementing practical, high-impact projects with clear ROI, such as conversational AI interfaces, retrieval-augmented generation (RAG) systems for knowledge management, or AI-powered demand forecasting. These solutions, often offered through AIaaS platforms, enable incremental adoption and scalable costs, making AI more accessible and cost-effective.

What’s Next for Robots? [MIT Tech Review]

The robotics landscape is undergoing significant transformations, driven by advancements in artificial intelligence, simulation technologies, and innovative physical designs. Companies like Figure AI, Tesla, and Agility Robotics are pushing boundaries in humanoid robotics. Figure AI’s humanoids are being tested with BMW, while Agility Robotics has deployed its Digit humanoids in GXO Logistics facilities for tasks like unloading pallets. However, challenges like battery life, charging logistics, and integration into busy human-centric environments highlight the gap between lab performance and real-world applicability. AI and simulation technologies are rapidly accelerating robotic learning. Robots can learn tasks by observing videos or simulations rather than relying on explicit coding. NVIDIA’s Cosmos, a “world foundation model,” uses 20 million hours of video to generate synthetic training data. This enables robots to simulate environments like hospitals and adapt to various scenarios, reducing costs and enhancing robot performance in specialized settings. Physical advancements in robotics are also gaining momentum. Gecko Robotics, for example, has developed machines that climb vertical surfaces using magnets for infrastructure inspections. Meanwhile, the U.S. military is investing in autonomous drones and unmanned undersea vehicles for defense applications, reflecting a shift in focus toward future conflicts in maritime environments, such as a potential Pacific confrontation between China and Taiwan. Collectively, these innovations point to a future where robots are more adaptable, intelligent, and capable of working in diverse environments.

Top 5 Global Robotics Trends for 2025 [IFR]

The global industrial robotics market has reached a record value of $16.5 billion, with 4 million robots now operating in factories worldwide, according to the most recent report of the International Federation of Robotics (IFR). Integrating AI technologies enables robots to handle complex tasks more efficiently. Analytical AI processes extensive sensor data to optimize operations, while physical AI uses virtual environments for self-training, improving robot performance. Humanoid robots, while still primarily single-purpose tools are gaining traction in industries like automotive and warehousing. These robots offer potential advantages in logistics and assembly tasks but face challenges in scalability and economic viability compared to traditional automation solutions. Next, robots are critical in achieving sustainability goals by reducing waste, improving production efficiency, and scaling green technologies like solar panels and EV batteries. Innovations such as energy-efficient lightweight designs, advanced grippers, and sleep-mode technologies make robotics systems more environmentally friendly. Finally, SMEs are beginning to adopt robotics through flexible models like Robotics-as-a-Service (RaaS), eliminating high upfront costs. Low-cost robotics solutions are also emerging to cater to applications with minimal precision or payload requirements.

Research:

FAST: Efficient Robot Action Tokenization [Physical Intelligence]

Researchers at Physical Intelligence have introduced FAST, a new action tokenizer designed for robotics that significantly improves the training efficiency and capability of vision-language-action (VLA) models for complex robotic tasks. Traditional tokenization methods, such as discrete binning, fall short of high-frequency, dexterous tasks like folding laundry or bussing tables. FAST addresses this limitation by leveraging the Discrete Cosine Transform (DCT), commonly used in signal compression, and combining it with Byte Pair Encoding (BPE) to create a compact representation of robot action sequences. This approach compresses raw action data into dense tokens, achieving up to 10x compression compared to earlier methods and 5x Faster Training compared to diffusion-based alternatives while maintaining comparable performance on complex, dexterous tasks. Finally, for the first time, researchers trained a generalist policy on the DROID dataset, which includes diverse robot manipulation tasks across various environments. With FAST, robots could follow natural language instructions and perform tasks zero-shot in new settings, such as university labs and households. FAST seamlessly integrates with modern transformer pipelines, improving transfer learning from large-scale pretraining and enabling robots to have better language instruction-following capabilities. It has been made publicly available, allowing researchers to train their policies using just a few lines of code. FAST represents a significant step in bridging robotics and modern AI training techniques. It provides a scalable and efficient framework for training generalist robot policies capable of handling complex tasks with precision and adaptability.

The Stellantis Data Hub [AWS for Industries]

The Data & Software Hub (DASH) framework is a comprehensive, technology-agnostic solution for managing data and software products across global organizations, addressing fragmented systems, silos, and inefficient access through secure storage, seamless sharing, collaborative development, and efficient analysis. Designed to meet modern demands such as generative AI, software-defined vehicles, and service-based models, DASH integrates core features like a centralized asset catalog for improved discovery and operational efficiency, a decentralized producer-consumer model with self-service capabilities, a unified enterprise portal for governance and traceability, a scalable multi-account and multi-region strategy, and centralized governance with automated workflows. Demonstrated through Stellantis, DASH has enabled secure sharing of vehicle data to enhance transparency and streamlined video data ingestion using GPU resources for cost-effective and scalable processing. DASH supports a culture of accountability, compliance, and innovation by promoting collaboration, integrating disparate data sources, and enabling rapid scaling of shared capabilities. It is a transformative framework for thriving in data-driven, software-centric industries.

Podcasts/Video:

The Dutch Company Powering The US Stock Market

Finance & Transactions 🏭💵

Venture Capital:

Ati Motors - A indian company producing autonomous mobile robots for factories and warehouses.

$20 million [Series B] - Led by Walden Catalyst Ventures and NGP Capital

Basetwo AI - A company building an AI-powered copilot for manufacturing engineers to optimize production processes in industries such as pharmaceuticals, consumer goods, and gas processing.

$11.5 million [Series A] - Led by AXA Venture Partners and joined by Glasswing Ventures, Deloitte Ventures, and others

BPR Hub - A company providing a cloud-based compliance management system for manufacturing companies.

$2.6 million [Seed] - Led by Accel and Kae Capital

Planned Downtime 🏭🧑🔧

The Court of Gold