Breaking the Bottleneck | Issue 95

[9/29/2025] Humanoid Dexterity, An Economic Analysis of Tariffs, NVIDIA Penetration Free Sim, & a new Gemini 1.5 release!

Breaking the Bottleneck is a weekly manufacturing technology newsletter with perspectives, interviews, news, funding announcements, manufacturing market maps, 2025 predictions, and more!

💥 If you are building, operating, or investing in manufacturing, supply chain, or robots, please reach out - aditya@machinafactory.org I’d love to chat!

🏭 If you were forwarded this and found it interesting, please sign up!

Content I Enjoyed Last Week 🗞️🔬 📚

A Couple of Big Things:

Why Today’s Humanoids Won’t Learn Dexterity [Rodney Brooks]

Rodney Brooks presents a compelling perspective on why today’s humanoids will not achieve dexterity, arguing that success requires collecting the correct data and applying the proper learning mechanisms. The correct data must include touch and force sensing, as humans possess approximately 17,000 mechanoreceptors in their hands alone. These mechanoreceptors are part of 15 different families of touch-sensing neurons, providing rich feedback on force, texture, and pressure that cannot be captured through visual observation alone. Research demonstrates that poor sensory reception increases task completion time for simple tasks, such as lighting a match, by a factor of four.

The question of the right learning mechanism remains a hotly debated topic. Richard Sutton (linked below) argues that today’s LLMs are not learning from experience, but rather being conditioned to predict the next best token, making LLMs a dead end. Brooks similarly contends, noting that LLMs rely on tokenization and embedding systems that capture linguistic structure and word relationships. Furthermore, speech recognition and image recognition using CNNs heavily rely on domain-specific preprocessing that mimics human physiology, rather than on experiential learning.

How Many Manufacturing Jobs Will Trump’s Tariffs Create? And at What Cost? [AEI; Gary Clyde Hufbauer & Ye Zhang]

The AEI analysis reveals that Trump’s tariff strategy fundamentally misunderstands modern manufacturing economics. As household incomes rise, consumption naturally shifts toward services rather than manufactured goods, creating a structural change that cannot be reversed through trade policy. Even eliminating the entire $300 billion manufacturing trade deficit would only restore manufacturing employment to roughly 10% of the workforce, far below the 1960s peak of 27%. This gap persists because productivity gains in manufacturing consistently outpace the broader economy, meaning fewer workers are needed to produce more output.

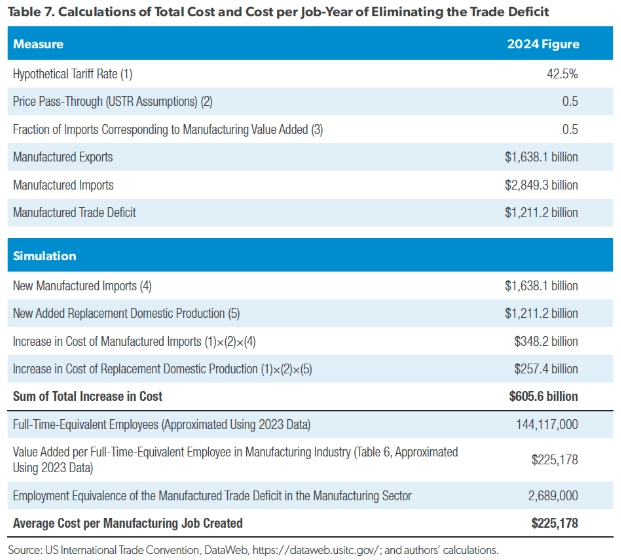

The economic costs prove prohibitive: achieving deficit elimination would require an average tariff of 42.5%, double Trump’s implemented 22.5% rates, and would burden American consumers with $225,000 to $550,000 annually per manufacturing job created. This translates to $605 billion to $1.2 trillion in higher prices across the economy each year. The analysis demonstrates that tariff-based industrial policy overlooks the true drivers of manufacturing job decline, namely shifts in consumer preferences and technological productivity gains, while creating significant economic inefficiencies. Better outcomes could be achieved through targeted skills-based training, similar to the new microelectronics major at CMU, and community assistance programs focused on high-skill manufacturing positions.

Other Reads:

NVIDIA solves penetration-free simulation, unlocking a vast number of scenarios and potential use cases that could transform the face of Digital Twins and synthetic data created for robotics applications. Here is the full paper! [NVIDIA and University of Utah]

Ananya Vasagiri, an investor at Schematic Ventures, provides a quick summary and recap of some of the best papers coming out of CoRL. A few highlights include:

X-Sim: Real-to-Sim-to-Real framework using object motion to reconstruct a photorealistic scene, train RL and diffusion policies, then deploy with an online domain adaptation technique

FetchBot: Sim-to-Real framework predicts depth from RGB inputs via a foundation model and adds local occupancy prediction for object-fetching in clutter

ClutterDexGrasp: Teacher-student framework with a simulation-trained teacher and 3D diffusion student for zero-shot dexterous grasping in clutter

Real2Render2Real: Uses 3D Gaussian Splatting to generate flexible assets and convert to meshes, ideal for VLA models and imitation learning

MULTIGEN: Brings large-scale generative models into physics simulators, starting with audio feedback and zero-shot transfer to a real-world pouring task

TSMC revealed a potential 10x boost in energy efficiency for AI computing chips, leveraging AI software from Cadence and Synopsys. Jim Chang, deputy director at TSMC for its 3DIC Methodology Group, said during a presentation, “This thing runs five minutes while our designer needs to work for two days.” [Reuters]

Security researchers have discovered a critical vulnerability in the BLE Wi-Fi configuration interface used by Unitree robots, which could allow an attacker to gain root-level access. [IEEE Spectrum]

An interview with Stephanie Lang, director of Amazon Business, reflecting the group’s first 10 years as well as its introduction of smart AI tools, bulk ordering, and Amazon Business Restock, its smart inventory restocker. [Industrial Distribution]

Great post from Vatsal Shah, the CEO of Litmus, on some of the trials and tribulations of building an early-stage manufacturing startup under the guidelines of Venture Capital. [LinkedIn]

Boeing’s defense arm announces partnership with Palantir, with plans to utilize its Foundry platform across its network of defense factories in the U.S., which build aircraft, helicopters, satellites, spacecraft, missiles, and weapons. [Reuters]

The WEF offers a framework for Gen Z as the new backbone for manufacturing and shares examples from The Academy of Advanced Manufacturing, a collaboration among ManpowerGroup and Rockwell Automation. The program has trained over 470 automation technicians, with graduates seeing 11% wage growth compared to past roles [WEF]

Products and Announcements:

Google launches new Gemini models, enabling robots to better reason, plan, utilize digital tools like Search, and transfer learning from one type of robot to another. Gemini 1.5 is a VLA model that turns visual information into motor commands, and Gemini 1.5 ER is a VLM that reasons and creates multi-step plans to complete a mission. [Google]

Verdantix evaluated nineteen key vendors within the rapidly evolving Industrial AI Analytics market based on product capabilities and business momentum. Check out the report here! [Verdantix]

Breakdown of General Motors’ pre-production vehicle manufacturing VR program. Launched in 2022, the program allows workers across the company to collaborate in virtual plants and assemble vehicles years before physical prototypes are built. This year alone, it has identified 494 manufacturing issues, saving significant time and money on physical prototypes that can cost up to $100,000 each. [USA Today]

Applied Materials announced a partnership with GlobalFoundries to develop and produce high-volume waveguide components and accelerate AI-powered photonics development.[Applied Materials]

Autodesk launches Neural CAD, “a category of generative AI models trained to directly reason both about CAD objects and industrial and architectural systems.” [Autodesk]

ENEOS Material revealed some of the results from its implementation of ChatGPT Enterprise. Early results have shown that 80% of employees reported significant improvements in their workflows during their pilot phase. There was a 90% reduction in data aggregation and analysis time for the HR department, and complex calculations and advanced inquiries can now be executed rapidly with Deep Research. [OpenAI]

Podcasts & Blogs:

America Can’t Lose the Robotics Race [

]Friday 5 with Chris Burchett [

]Jay Douglass, the CEO of the ARM Institute [Manufacturing Happy Hour]

Finance & Transactions 💵

Beroe - A company building a procurement decision intelligence platform.

$34 million [Financing] - From Relativity Resilience Fund and Alchemy Long Term Ventures Fund

Telo Trucks - A company building an all-electric mini truck.

$20 million [Financing] - Led by Yves Behar and Tesla co-founder Marc Tarpenning, and joined by E12 Ventures, Neo, and Marc Benioff.

Holy Technologies - A German company building an autonomous factory for lightweight components.

€4.3 million [Seed] - From Rockstart, Vanagon, SANDS, Innovationsstarter Fonds Hamburg, and EIT Manufacturing.

Job of the Week:

Diagon, a company building the next-generation platform for sourcing high-tech manufacturing equipment, is hiring for a Principal AI Engineer

Planned Downtime 🧑🔧

One Battle After Another Breakdown [The Big Picture]

Father of RL Thinks LLMs are Dead [Dwarkesh Patel]